Exemplar is a recognized name in the domestic & international markets. Our fully integrated manufacturing unit and in-house Laboratory and Testing facility not only help us offer products conforming to most stringent customer specifications, but also develop new products and solutions for the most demanding of sectors.

Our Inhouse state of art testing facility gives us the ability to develop products at record time as well as offer customised products and solutions to the complete satisfaction of our esteemed customers.

Our ability to adhere to stringent quality specifications making us the supplier of choice among some of the largest wire rope manufacturers globally.

Our cores are tested as per the procedures outlined in ISO 4345.

From Raw Material to the finished products, we have the in-house ability to conduct:

⦁ Chemical analysis

⦁ Yarn Quality Verification

⦁ In process and final inspection related to Diameter of Cores/Ropes

⦁ Lubricant Content in our finished products

⦁ Other physical attributes as suggested by the customers.

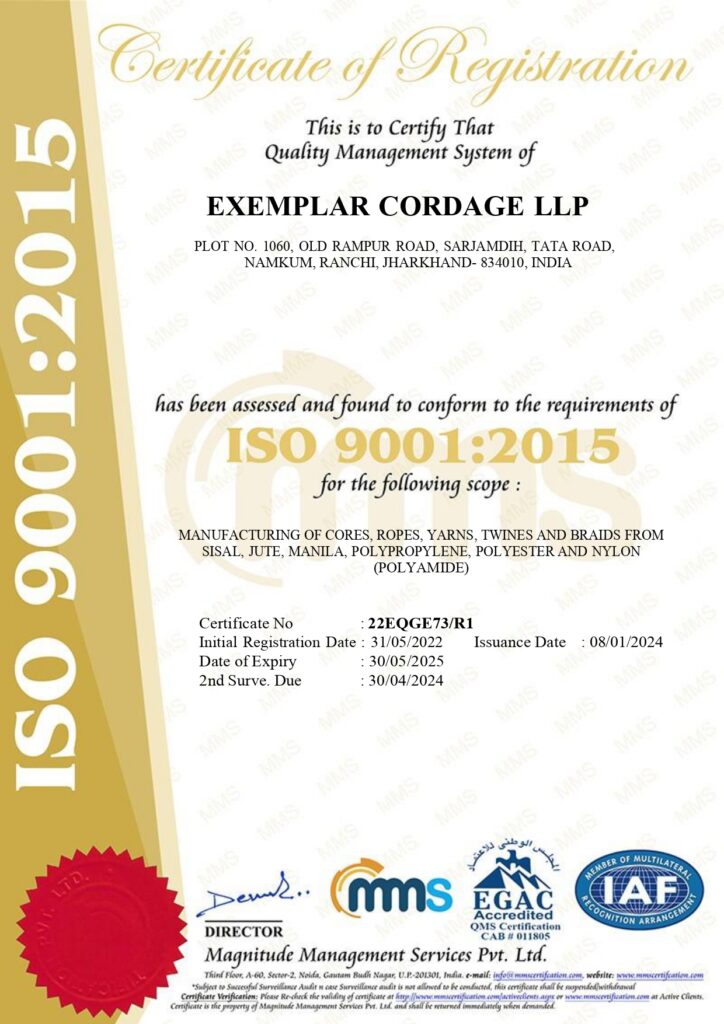

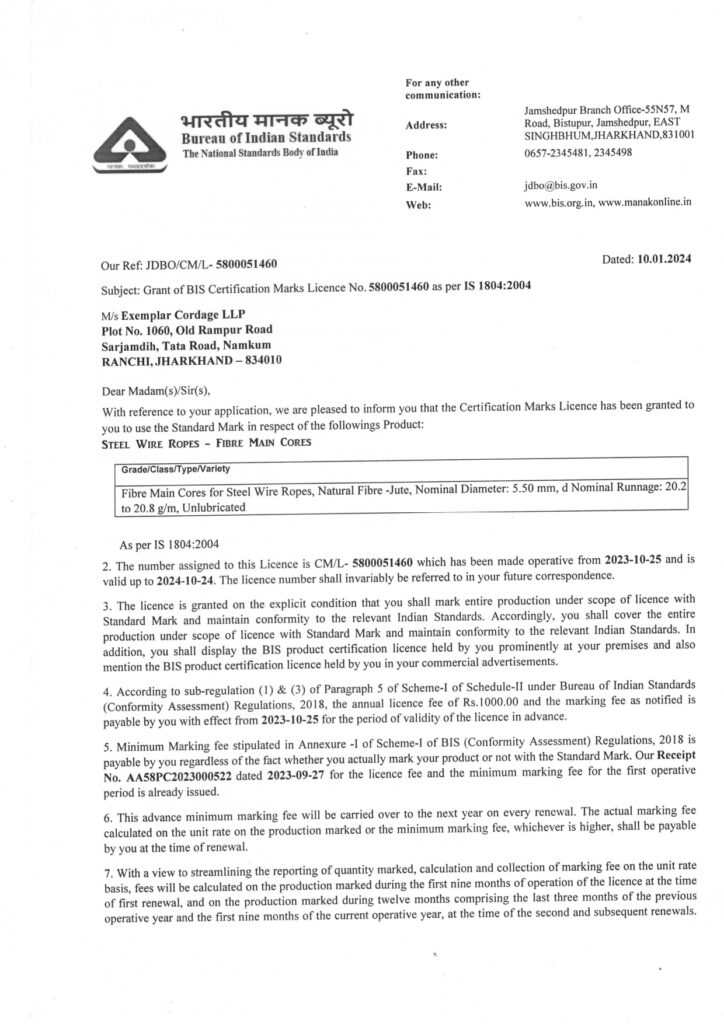

Exemplar Cordage LLP is an ISO 9001:2015 certified company, which manufactures and exports high-quality ropes, core, yarns, twines, & braids from both natural and manmade fibers like Sisal, Manila, Jute, Polypropylene, Polyester, Nylon, etc.

Copyright © 2024 Exemplar Cordage LLP. All Right Reserved.

| 1. | Offered in both dry and pre-lubricated variety. |

| 2. | Selection of Lubricants such as T55, Elaskon SKU, N65, N113 etc |

| 3. | Available in 3 or 4 strands in Z or S twist as per requirement |

| 4. | Can be packed in coils or Wooden Reels that can accommodate 200 to 500 Kgs of cores in longer lengths |

| Availability | Available in Left or Right Twist |

| Selection | Clipped or Un-Clipped |

| Weight | Offered in 1250 m/kg to 200m/kg |

| Packing | Packages in Cheese Spools of dimensions and weight as required by the customer |

| Size | Features | Advantages |

|---|---|---|

| As per your requirement | High perforfance Polypropylene Yarns | Great for cross training. Improving one’s overall fitness level. Great for strength, power and cardiovascular endurance. |

| Colour as per your requirement | Extra Durable |

High Lights:

– Available in sizes as per requirement

– Polypropylene Nets can be in any colour as per requirement

– Long Lasting

– Strong

Nylon (Polyamide) /Polyester/Polypropylene braids offer high strength, reliability and flexibility. These can be made with Hollow/Solid core and in any colour as may be required with or without UV treatment. Currently available in 3-12mm diameter.

Our Fishing Twines are made with superior-quality yarns for great performance and life in the most demanding marine conditions.

Our fishing ropes offer abrasion resistance and can be made to individual colour requirements in three and four strands.

| Size | Twist | Features | Advantages |

|---|---|---|---|

| As Per Requirement | LH/RH | High Grade Stainless Steel Wires, Enhanced Polyprylene Yarns | Extra Durable |

| Size (mm) | Features | Break Strength |

|---|---|---|

| 2 | Prime quality Jute Yarns | 50 |

| Denier | Twist | Features | Break Strength |

|---|---|---|---|

| 14400 | LH/RH | Split Film Polypropylene Yarns | 50 |

| 18000 | LH/RH | 72 | |

| 20000 | LH/RH | 80 | |

| 24000 | LH/RH | 96 |

Our PP ropes designed for cable pulling and tower erection are known for their strength, durability and abrasion resistance.

Our PP ropes specifically designed for installation of submersible pumps provide the highest safety due to their strength, durability and endurance.

| “Dia (mm)” | Manila Rope | Sisal Rope | Manila Rope | Sisal Rope | ||||

|---|---|---|---|---|---|---|---|---|

| Linear Densiy (g/m) | Linear Densiy (g/m) | Breaking Strength (min.) kN (kgf) | Breaking Strength (min.) kN (kgf) | |||||

| 3 Strands | 4 Strands | 3 Strands | 4 Strands | 3 Strands | 4 Strands | 3 Strands | 4 Strands | |

| 6 | 32 | N/A | 29 | N/A | 2.94 (303) | 2.550 (260) | N/A | |

| 8 | 54 | 54 | 54 | N/A | 5.45 (556) | 4.81 (490) | 4.735 (483) | N/A |

| 10 | 68 | 68 | 68 | N/A | 7.04 (718) | 6.27 (639) | 6.226 (635) | N/A |

| 12 | 105 | 105 | 105 | 105 | 10.64 (1 085) | 9.41 (960) | 9.363 (955) | 8.431 (860) |

| 14 | 140 | 140 | 140 | 140 | 14.50 (1 479) | 12.80 (1 305) | 12.698 (1 285) | 11.324 (1 155) |

| 16 | 190 | 190 | 190 | 190 | 20.30 (2 070) | 17.90 (1 825) | 17.696 (1 804) | 15.931 (1 624) |

| 18 | 220 | 220 | 220 | 220 | 24.40 (2 488) | 21.53 (2 195) | 20.932 (2 134) | 18.824 (1 919) |

| 20 | 275 | 275 | 275 | 275 | 32.40 (3 304) | 28.68 (2 924) | 27.981 (2 853) | 25.098 (2 559) |

| 22 | 330 | 330 | 330 | 330 | 38.59 (3 935) | 34.08 (3 067) | 33.383 (3 404) | 30.049 (3 064) |

| 24 | 400 | 400 | 400 | 400 | 45.70 (4 660) | 40.36 (4 116) | 39.853 (4 064) | 35.883 (3 659) |

| 26 | 470 | 470 | 470 | 470 | 53.35 (5 440) | 47.07 (4 800) | 46.324 (4 724) | 41 .667 (4 249) |

| 28 | 532 | 532 | 532 | 532 | 60.94 (6 214) | 53.79 (5 485) | 52.206 (5 323) | 46.961 (4 789) |

| 30 | 625 | 625 | 625 | 625 | 68.59 (6 994) | 60.56 (6 175) | 59.755 (6 093) | 53.775 (5 483) |

| 32 | 740 | 700 | 700 | 700 | 78.75 (8 030) | 69.53 (7 090) | 67.255 (6 858) | 60.540 (6 173) |

| 36 | 890 | 890 | 890 | 890 | 96.50 (9 840) | 85.17 (8 685) | 84.637 (8 630) | 85.981 (8 767) |

| 40 | 1 100 | 1 100 | 1100 | 1100 | ||||

| Manila Rope | Sisal Rope | |||||||

|---|---|---|---|---|---|---|---|---|

| Linear Densiy (g/m) | Linear Densiy (g/m) | Breaking Strength (min.) kN (kgf) | Breaking Strength (min.) kN (kgf) | |||||

| 3 Strands | 4 Strands | 3 Strands | 4 Strands | 3 Strands | 4 Strands | 3 Strands | 4 Strands | |

| 6 | 32 | N/A | 29 | N/A | 2.94 (303) | 2.550 (260) | N/A | |

| 8 | 54 | 54 | 54 | N/A | 5.45 (556) | 4.81 (490) | 4.735 (483) | N/A |

| 10 | 68 | 68 | 68 | N/A | 7.04 (718) | 6.27 (639) | 6.226 (635) | N/A |

| 12 | 105 | 105 | 105 | 105 | 10.64 (1 085) | 9.41 (960) | 9.363 (955) | 8.431 (860) |

| 14 | 140 | 140 | 140 | 140 | 14.50 (1 479) | 12.80 (1 305) | 12.698 (1 285) | 11.324 (1 155) |

| 16 | 190 | 190 | 190 | 190 | 20.30 (2 070) | 17.90 (1 825) | 17.696 (1 804) | 15.931 (1 624) |

| 18 | 220 | 220 | 220 | 220 | 24.40 (2 488) | 21.53 (2 195) | 20.932 (2 134) | 18.824 (1 919) |

| 20 | 275 | 275 | 275 | 275 | 32.40 (3 304) | 28.68 (2 924) | 27.981 (2 853) | 25.098 (2 559) |

| 22 | 330 | 330 | 330 | 330 | 38.59 (3 935) | 34.08 (3 067) | 33.383 (3 404) | 30.049 (3 064) |

| 24 | 400 | 400 | 400 | 400 | 45.70 (4 660) | 40.36 (4 116) | 39.853 (4 064) | 35.883 (3 659) |

| 26 | 470 | 470 | 470 | 470 | 53.35 (5 440) | 47.07 (4 800) | 46.324 (4 724) | 41 .667 (4 249) |

| 28 | 532 | 532 | 532 | 532 | 60.94 (6 214) | 53.79 (5 485) | 52.206 (5 323) | 46.961 (4 789) |

| 30 | 625 | 625 | 625 | 625 | 68.59 (6 994) | 60.56 (6 175) | 59.755 (6 093) | 53.775 (5 483) |

| 32 | 740 | 700 | 700 | 700 | 78.75 (8 030) | 69.53 (7 090) | 67.255 (6 858) | 60.540 (6 173) |

| 36 | 890 | 890 | 890 | 890 | 96.50 (9 840) | 85.17 (8 685) | 84.637 (8 630) | 85.981 (8 767) |

| 40 | 1 100 | 1 100 | 1100 | 1100 | 119.60 (12 196) | 105.37 (10 745) | 102.109(10412) | 91.912 (9372) |

| Material | UV Stabilized Fibrillated – danline Polypropylene Split Film |

| Construction | 3-Strand |

| Specific Gravity | 0.92 |

| Melting Point | 165°C |

| Dry & Wet Conditions | Identical dry & wet strengths |

| U.V. Resistance | Good |

| Chemical Resistance | Very Good |

| Dia in MM (3 Strand) | Wt./coli of 220 MTR | Break Strength (Kgf) |

|---|---|---|

| 4.0 | 1.8 | 286 |

| 6.0 | 4.1 | 612 |

| 8.0 | 7.3 | 1120 |

| 10.0 | 11.4 | 1530 |

| 12.0 | 16.5 | 2162 |

| 14.0 | 22.4 | 2856 |

| 16.0 | 29.3 | 3825 |

| 18.0 | 37.1 | 4590 |

| 20.0 | 45.8 | 5712 |

| 22.0 | 55.4 | 6834 |

| 24.0 | 65.9 | 8160 |

| 26.0 | 77.3 | 9180 |

| 28.0 | 89.7 | 10812 |

| 30.0 | 103.0 | 12036 |

| 32.0 | 117.1 | 13464 |

| 36.0 | 148.3 | 17340 |

| 40.0 | 183.0 | 20400 |

| Material | UV Stabilized Polyester Yarns |

| Construction | 3/4 Strand |

| Specific Gravity | 1.38 |

| Melting Point | 250°C |

| Chemical Resistance | Excellent |

| U.V. Resistance | Very Good |

| Abrasion Resistance | Very Good |

| Dia in MM (3 Strand) | Wt./coli of 220 MTR | Break Strength (Kgf) |

|---|---|---|

| 4.0 | 2.6 | 290 |

| 6.0 | 5.9 | 554 |

| 8.0 | 10.6 | 1000 |

| 10.0 | 16.5 | 1560 |

| 12.0 | 23.8 | 2230 |

| 14.0 | 32.3 | 3120 |

| 16.0 | 42.2 | 3980 |

| 18.0 | 53.5 | 4980 |

| 20.0 | 66.0 | 6230 |

| 22.0 | 79.9 | 7470 |

| 24.0 | 95.0 | 8960 |

| 26.0 | 111.5 | 10500 |

| 28.0 | 129.4 | 12000 |

| 30.0 | 148.5 | 13400 |

| 32.0 | 169.0 | 15400 |

| 36.0 | 213.8 | 19000 |

| 40.0 | 264.0 | 23500 |

| Material | Multifilament Yarns |

| Construction | 3/4 Strand |

| Specific Gravity | 1.14 |

| U.V. Resistance | Very Good |

| Abrasion Resistance | Excellent |

| Chemical Resistance | Excellent |

| Melting Point | 215°C |

| Dry & Wet Conditions | Strength decreases 15% when wet |

| Dia in MM (3 Strand) | Wt / coil of 220 MTR |

Kgf |

|---|---|---|

| 4.0 | 2.3 | 320 |

| 6.0 | 5.1 | 750 |

| 8.0 | 9.2 | 1345 |

| 10.0 | 14.3 | 2088 |

| 12.0 | 20.6 | 2995 |

| 14.0 | 28.0 | 4095 |

| 16.0 | 36.6 | 5300 |

| 18.0 | 46.3 | 6695 |

| 20.0 | 57.2 | 8300 |

| 22.0 | 69.2 | 10000 |

| 24.0 | 82.4 | 12000 |

| 26.0 | 96.7 | 13950 |

| 28.0 | 112.1 | 15800 |

| 30.0 | 128.7 | 17755 |

| 32.0 | 146.4 | 20000 |

| 36.0 | 185.3 | 24500 |

| 40.0 | 228.8 | 30000 |

| Material | High precision Jute Yarns |

| Construction | 3-Strand, 4 Strand (as per your specifications) |

| Size | As per your specifications |

| Material | Special Precision Polypropylene Yarns |

| Construction | 3-Strand, 4 Strand (as per your specifications) |

| Size | As per your specifications |

| Colour | As per your requirement |

| Melting Point | 165°C |

| Dry & Wet Conditions | Identical dry & wet strengths |

| U.V. Resistance | Good (if asked for) |

| Packaging | Coils/Reels as per your specifications |